Site Search

Search within product

第743号 2022 (R04) .08-09発行

Click here for PDF version

農業と科学 令和4年8-9月

本号の内容

§ Coated phosphorus nitrate and phosphorus nitrate in open-air summer/autumn green onion

リン酸質肥料のチェーンポット内施肥技術

地方独立行政法人 北海道立総合研究機構

Donan Agricultural Experiment Station, Agricultural Research Division

Research Department Production Technology Group

主任主査(栽培環境) 大橋 優二

§上益城地域における農協営農活動の変遷と私の出合

農事組合法人 かしま広域農場

Former President and Representative Director

(現 特別顧問)工藤 健一

No § Soil - No. 14

養分源が堆肥から化学肥料へ変化する時代

−その歴史的経緯−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Coated phosphorus nitrate and phosphorus nitrate in open field summer/autumn green onion

リン酸質肥料のチェーンポット内施肥技術

地方独立行政法人 北海道立総合研究機構

Donan Agricultural Experiment Station, Agricultural Research Division

Research Department Production Technology Group

主任主査(栽培環境) 大橋 優二

Introduction

全国のねぎの出荷量(令和元年)は千葉県の約59千tに次いで埼玉県,茨城県,群馬県が上位を占め,北海道は約20千tを出荷する全国5位のねぎ生産地である1)。北海道のねぎ栽培は主に渡島地域(北海道の南西部)や空知地域(同中央部) ,十勝地域(同南東部)で盛んに行われている。とくに渡島地域は道内収穫量の37%(令和元年)と多くを占めており,道外への出荷量が約5千tと他地域に比べ5〜10倍多い2)The following is a list of the most common problems with the "C" in the "C" column.

露地ねぎ栽培では秋冬期に生産量が多い関東の生産地に対し,気象条件が異なる北海道は夏秋どりが主流である。露地春まき夏秋どり作型の窒素施肥量は作付け前の土壌診断に基づく施肥対応3)で「9〜18kg/10a(分施1〜2回)」と示されているが,生産現場では多肥栽培を行う事例も多く見受けられ,環境負荷低減やコスト削減の観点からも窒素減肥技術の開発が求められる。

Under these circumstances, the use of fertilizer with regulated fertilizer efficacy, which enables the supply of nutrients according to the growth stage of the crop, is increasing in the production of other crops. These fertilizers include "coated phosphorus nitrate" that gradually releases nitrogen nutrients in response to temperature and moisture in the soil, and especially the "sigmoid type," which suppresses nitrogen release in the early stages, can be used at the seedling stage without adversely affecting the growth of seedlings. As a result, the entire amount of nitrogen required for cultivation in the open field (hereinafter referred to as "main field") after planting can be applied at the seedling stage, which is expected to reduce fertilizer use and reduce fertilizer application work in the main field through improved fertilizer application efficiency.

これまでに被覆燐硝安系を利用した育苗ポット内への施肥技術がキャベツ4),たまねぎ5),トマト6)等で報告されている。また,ねぎでは関東地方の夏どり,および冬どりの作型で被覆燐硝安を育苗時のチェーンポット内へ施肥し,施肥効率の向上ならびに本圃の施肥作業の省略が可能となる技術が開発されている7) , 8)。本技術はねぎの作型や施肥量が異なる北海道においても有用と考えられる。一方,リン酸については育苗ポット(セル)内へのリン酸施肥により,キャベツではリン酸施肥量の慣行比50%以上の削減効果9)や,たまねぎでは初期生育の向上ならびに収量の安定化10)が報告されている。

In this paper, we report on the development of a technique for applying nitrogen and phosphoric acid, either separately or simultaneously, in chain pots during seedling growth using coated phosphorus nitrate and phosphate fertilizers in open field summer/fall leek cultivation in Hokkaido, Japan.

2. test conditions

Seedlings were grown in unheated plastic greenhouses at the Donan Agricultural Experiment Station (Hokuto City, Hokkaido) and planted in the main field (brown lowland soil) from 2011 to 2013 (three consecutive years). The test cultivar was "Shirahane Ipponta" and the crop types were "September sowing (sown in March)" and "October sowing (sown in April)" for spring, summer, and fall sowing.

Seedlings were sown in chain pots CP303 (264 holes/book) in a nonheated plastic greenhouse, with two seedlings per hole (seedlings grown on the ground), and "Nitten Onion Medium D (660 mg/L nitrogen - 2500 mg/L phosphoric acid - 100 mg/L potash)" was used as seedling culture medium. For in-chain pot fertilization, a mixture of coated phosphorus nitrate and phosphate fertilizer prepared using a fertilizer mixer and seedling medium was filled into CP303, and seedlings were sown and grown in the same manner. The seedlings were planted using the "Hittari-kun" transplanter at a planting density of 44,444 plants/10a (90 cm between plants, 5 cm between plants) in mid-May for September planting and in mid-June for October planting.

対照区の本圃施肥量は作付け前の土壌分析値(熱水抽出性窒素−トルオーグリン酸−交換性カリ=1.2−32−43mg/100g)に基づき施肥対応11)を行った。すなわち,9月どりでN−P2O5−K2O=[12+7]−15−[3+3]( [ ]内は基肥+分施) ,10月どりでN−P2O5−K2O=[10+4+4]−15−[4+2+2]とした。

3. nitrogen fertilization in chain pots of coated phosphorus nitrate

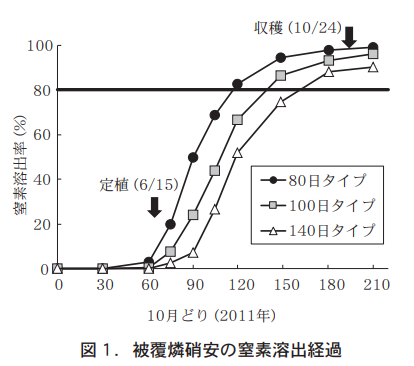

The "sigmoid type" of coated phosphorus nitrate (J-Cam Agri Co., Ltd.) was selected to minimize nitrogen leaching during the seedling period, and three types with different nitrogen leaching rates were used (80-, 100-, and 140-day types; the numbers are the number of days that 80% of the contained nitrogen leached out in soil at 25°C).

The number of days of nitrogen leaching (80% of nitrogen content) of coated phosphorus nitrate in the field after seedling growth and planting was examined in a burial test. The results showed that the nitrogen leaching from the 80-day type was about 150 days, 170 days, and 190 days in September, 100 days, and 140 days, respectively, and 120 days, 130 days, and 160 days, respectively, in October (Figure 1). Therefore, the 80-day type was considered unsuitable for use with in-pot nitrogen fertilization.

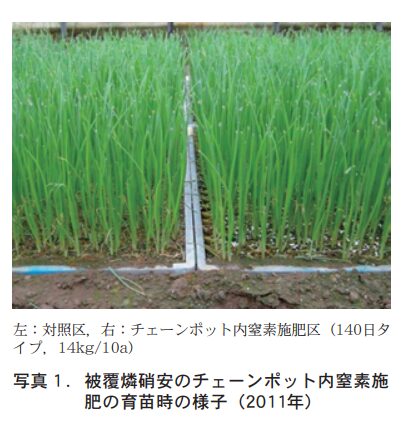

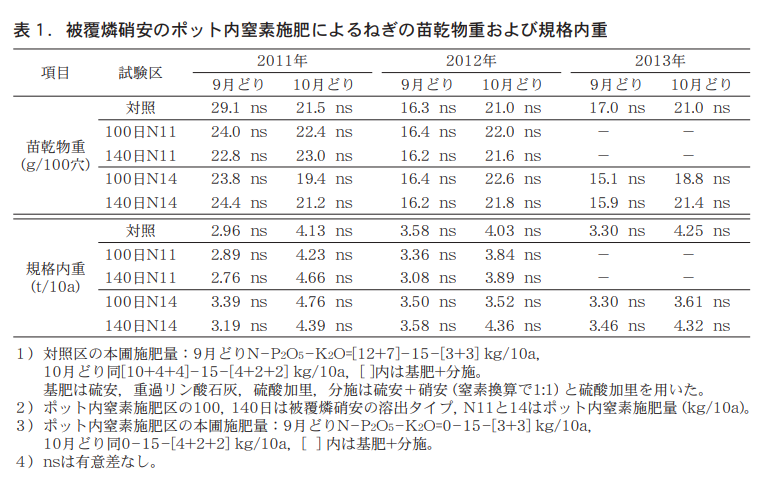

次に,被覆燐硝安100日,140日タイプとチェーンポット(以下,ポットと省略)内窒素施肥量(11,14kg/10a)を組み合わせたポット内窒素施肥系列(写真1)および対照区を設置した。なお,ポット内窒素施肥系列は本圃の窒素を無施肥とし,リン酸とカリはいずれの試験区も対照区と同一とした。

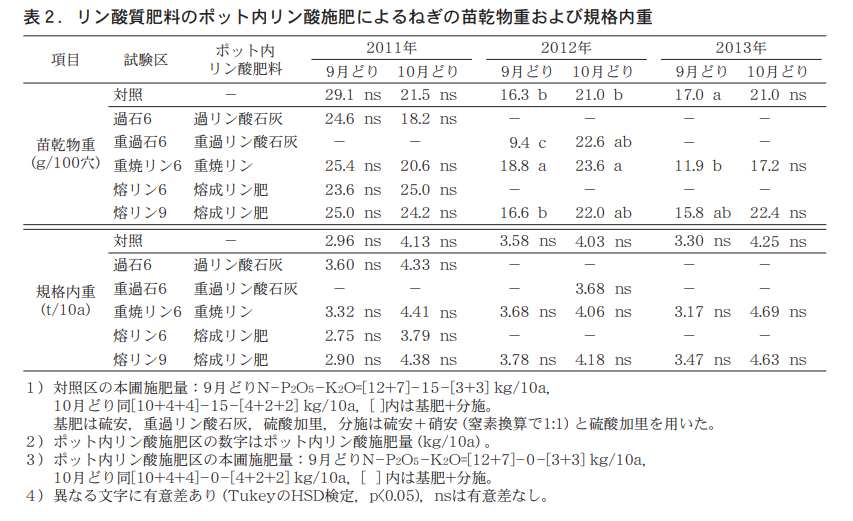

ポット内窒素施肥系列の苗乾物重(育苗終了時)はいずれの年次も9月どり,10月どりで対照区と処理間差はみられなかったが(表1上段) ,規格内重はポット内の窒素施肥量が多いほど概ね増加する傾向を示した(表1下段) 。また,9月どりでは同一施肥量における規格内重に明瞭な差はみられなかったが,10月どりでは100日タイプと比較して140日タイプで規格内重が優る傾向を示した。

The results showed that 14 kg/10a of in-pot nitrogen fertilizer was suitable for both September and October cropping, and the 140-day leaching type was the most effective type.

4. phosphate fertilization in chain pots of phosphate fertilizers

To determine the best phosphatic fertilizers for in-pot phosphate fertilization and the amount of fertilizer applied, we set up test plots combining two levels (6 and 9 kg/10a) of in-pot phosphate fertilization with superphosphate lime (overstones), heavy superphosphate lime (heavy overstones), heavy baked phosphorus, and dissolved phosphorus fertilizer (dissolved phosphorus). The test plots with in-pot phosphoric acid fertilization were not fertilized with phosphoric acid in the main field, and the nitrogen and potash amounts applied in the main field were the same in both test plots as in the control plot.

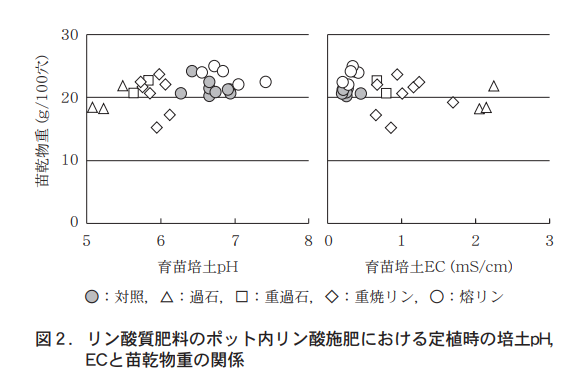

Looking through the results of the three-year trial on the effects of phosphatic fertilizers on seedling dry matter weight, we found that overstones, heavy overstones, and heavy burned phosphorus tended to reduce or decrease seedling dry matter weight compared to the control, but not soluble phosphorus (Table 2, top row). To clarify this factor, we examined the relationship between media pH and EC and seedling dry matter weight at planting.

When overstones, heavy overstones, and heavy burnt phosphorus containing water-soluble phosphoric acid components were used, the pH and EC of the medium decreased and the dry matter weight of seedlings tended to decrease (Figure 2). On the other hand, dissolved phosphorus, which does not contain water-soluble phosphoric acid, showed smaller changes in media pH and EC than other phosphatic fertilizers, and had less effect on seedling dry matter weight. These results suggest that the decrease in seedling dry matter weight associated with in-pot phosphate fertilization is due to a decrease in media pH and an increase in EC.

Next, looking at the three-year within-specification weights, no clear differences were observed between the September and October treatments in either year, suggesting that with phosphate fertility (32 mg/100 g) equal to or higher than that of the test plots in this study, the same within-specification weights as in the control plots could be obtained with a dissolved phosphorus application of 6 to 9 kg/10a, which has a slow initial fertilization effect (lower part of Table 2). (lower part of Table 2).

The results indicate that soluble phosphorus is suitable for in-pot phosphoric acid fertilization, and that phosphoric acid application amounts in the range of 6 to 9 kg/10a are appropriate.

5. simultaneous application of coated phosphorus nitrate and phosphate fertilizer in chain pots

The test plots were set up for simultaneous in-pot application of coated phosphorus nitrate and phosphate fertilizer, combining a nitrogen fertilizer rate of 14 kg/10a of coated phosphorus nitrate (140-day type) with an in-pot phosphoric acid rate of 6 or 9 kg/10a of soluble phosphorus. In the test plot with simultaneous in-pot fertilization, no nitrogen or phosphate was applied in the main field, and the amount of potash applied in the main field was the same in both test plots as in the control plot.

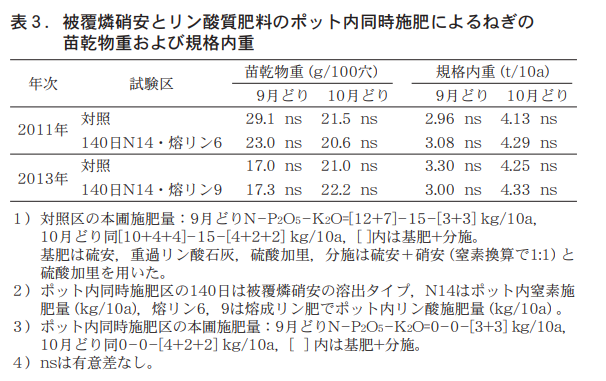

The results of the two-year trial showed that the dry matter weight and in-specification weight of seedlings in the simultaneous in-pot fertilizer application area did not differ significantly from those in the control area, and were similar (Table 3).

These results indicate that the simultaneous in-pot application of coated phosphorus nitrate and phosphate fertilizer, combining coated phosphorus nitrate 140-day type at a nitrogen fertilizer rate of 14 kg/10a and soluble phosphorus at a phosphate fertilizer rate of 6 to 9 kg/10a, ensured healthy seedling growth and produced in-specification weights comparable to those in the control area.

6. utilization aspects and points to note

The results were obtained in a field with low nitrogen fertility (less than 3 mg N/100 g hot water extractable nitrogen) and phosphate fertility that fell within the "standard value (20 to 40 mg/100 g toluoroglycolic acid)" after planting, using a sigmoid-type phosphorus nitrate coating with low initial leaching as a nitrogen fertilizer. In this case, the use of this technology enables a reduction of up to 4 kg/10 a of nitrogen and 6-9 kg/10 a of phosphoric acid compared to the current fertilizer use3) , and eliminates the need for nitrogen and phosphoric acid fertilization in the main field.

In fields where phosphate fertility is below the standard value (toluoglinic acid less than 20 mg/100 g), it is recommended that the soil be amended to the standard value before introducing this technology.

References

(1) Ministry of Agriculture, Forestry and Fisheries 2019.Vegetable Production and Shipment Statistics.

2)北海道農業協同組合中央会・ホクレン農業協同組合連合会 2021.

北海道野菜地図,p58.

3)北海道農政部 2020.北海道施肥ガイド2020,p113.

北海道農業改良普及協会,北海道.

4)岩佐博邦・大塚英一・真行寺 孝・井上 満・小林広行 2005.

セル培養土内基肥施用によるキャベツの減窒素栽培.

千葉農総研研報,4.p23−31.

5)小野寺政行 2011.

移植タマネギにおける肥効調節型肥料を用いたポット内施肥法.

土肥誌,82,p312−315.

6)小杉徹・中村仁美・若澤秀幸 2007.

肥効調節型肥料を用いたトマト育苗鉢内全量施肥法.

土肥誌,78,p207−211.

7)山本二美・松丸恒夫 2007a.

夏どりネギにおけるチェーンポット内施肥の施肥窒素量と追肥窒素量の検討.

土肥誌,78,p179−186.

8)山本二美・松丸恒夫 2007b.

ネギのチェーンポット内全量窒素施肥が生育および収量に及ぼす影響.

土肥誌,78,p371−378.

9)千葉県農林総合研究センター平成26年度試験研究成果普及情報課題一覧

「野菜4.リン酸のセル内施肥によるキャベツのリン酸減肥」 .

10)小野寺政行・板垣英祐・古館明洋・木谷祐也・日笠裕治 2014.

移植タマネギにおける葉面散布およびポット内施肥を用いたリン酸減肥技術.

土肥誌,85,p245−249.

11)北海道農政部 2010.

北海道施肥ガイド2010,p108.北海道農業改良普及協会,北海道.

Changes in Agricultural Cooperative Farming Activities in the Kamimashiki Area and My Encounters

農事組合法人 かしま広域農場

Former President and Representative Director

(現 特別顧問)工藤 健一

Introduction.

The Kashima Regional Farm is located in Kashima-cho, in the southern part of Kumamoto City, and is the largest farm in Kyushu with 477 hectares of farmland (Figure 1). Currently, as a special advisor to Kashima Regional Farm, I am making efforts to establish paddy farming centering on paddy rice, wheat, and soybeans, and to improve farmers' income. In this paper, I would like to review the agricultural cooperative farming activities I have been involved in over the years.

Progression to becoming an employee of an agricultural cooperative

I was born the eldest son of a farmer, and my parents farmed rice, wheat, and silkworms on 1.5 ha of their own land. I graduated from a prefectural agricultural high school in 1959 as the successor to my parents, and went on to become a farmer.

In 1960, three of his classmates in the village introduced greenhouse horticulture, and in 1960, they introduced a 20-a greenhouse for growing greenhouse tomatoes, and worked hard to improve farmers' income through a combined management of rice, wheat, and greenhouse tomatoes. In 1970, the local Rokka Agricultural Cooperative Association requested him to become a farmer in order to strengthen the cooperative system, not only for rice and wheat farming, but also for horticulture and livestock breeding, as part of its vision for the future.

As a farm advisor for agricultural cooperatives, I have explained the advantages of cooperative system production materials to members and provided them with inexpensive, high-quality production materials to encourage them to engage in planned crop cultivation in the hope of improving productivity.

2. 2. Meeting with strain Kumiai Chisso Vinyl

In 1970, Kumamoto Keizairen (Kumamoto Economic Federation) launched a plan to establish cooperative farming complexes as a means of transport gardening, and worked to put cultivation into practice with the goal of becoming Japan's top producer of watermelons and melons.

The Rokka Agricultural Cooperative also established a melon club with 30 households engaged in greenhouse cultivation of Prince melons, and worked to improve the efficiency of joint work by dividing into two groups for joint seedling raising and joint vinyl covering of pipe greenhouses. Vinyl manufacturers such as Mitsubishi Monsanto, Mitsui Vinyl, and Kumiai Vinyl of the red line vinyl system were used by the farmers, but the joint work with Chisso Kumiai Vinyl, which I promoted, started at 5:00 a.m., and the poor quality of the vinyl, including tension, shrinkage, and stretching, was more noticeable than that of other manufacturers. This was the reason for the problem. I reported the current situation to the Chisso-Minamata Vinyl Laboratory and requested quality improvement. The laboratory worked to improve the quality of the vinyl by adding catholytic agents, etc., and the Melon Club also visited the laboratory and made an inspection of the quality of Kumiaye Vinyl (Chisso).

There were 15 to 16 agricultural cooperatives established in Kamimashiki County at that time, and the Kamimashiki County Economic Promotion Committee, which coordinates the production materials of the Kumamoto Economic Federation, had established a headquarters for promoting the business of the system, consisting of executives and employees of each agricultural cooperative. Each agricultural cooperative's share of the market for vinyl in the system was about 20%. In the meeting in charge of handling "Chisso Kumiai Vinyl," we proposed the expansion of 100% Chisso vinyl as a lineage product, explained the efforts of the Melon Club of Rokka NNK, and worked to strengthen the cooperative system for receiving orders for lineage vinyl (Chisso). The quality of Kumiai Vinyl was improved over the next three to four years, and it became a production material that can withstand year-round use as a strain of vinyl for spring and fall melon cultivation and continues to be used by horticultural farmers.

3. Special Cultivation Rice Initiatives

平成元年3月に嘉島町・御船町・甲佐町の3町の農協合併で旧上益城農業協同組合が発足した。その中で主食米の政府米と自主流通米の販売系統があったが,当農協は自主流通米の生産による農家所得向上の販売体制方向に「カジ」を切った。

In order to meet the needs of consumers for staple rice 10 years in the future, Kumamoto Prefecture also set a guideline for growing "health-conscious and environmentally friendly" rice. The efforts were discussed at a meeting of the agricultural cooperative's board of directors, the initiatives were announced, publicized and put into practice at a regional roundtable meeting, and a plan for profitable sales was formulated.

In 1997, three agricultural cooperatives in the prefecture were involved in this project. A joint meeting was held with related organizations to discuss a cultivation plan for 1,000 ha of flat land, but it was difficult to consolidate opinions at the meeting.

4. plan to collect the entire amount of agricultural cooperative country rice and introduce special rice cultivation

(1) The variety "Morinokuma-san" is designated as a unified special cultivation variety.

(2) Prepare a manual for the use of specially cultivated rice, exclusive fertilizers, exclusive designated pesticides, and use of the specially cultivated rice.

③嘉島,御船,甲佐管内で流通している生産資材(肥料)は,肥料成分を有機で取る為,価格高が生じるので栽培者に向けた説明マニュアルを作成する。

④農協カントリーエレベーター(以下,CEと表記)5,700t集荷体制(全量集荷)の内訳(図2) 。

Rokka CE 2,000 tons, Oshima CE 2,000 tons

Kosa CE: 1,000 tons, Mifune CE: 700 tons

Total 5,700t

⑤米販売体制は,自主流通協議会の販売計画の中で経済連・農協は中卸業者に特別栽培生産資材の品目別説明を行い有利販売に努める。

⑥特別栽培米各圃場には,特別栽培圃場の立板を用意し全筆に実施する。(嘉島管内で4,000筆)

5. special cultivation practices and meeting with JCAM Agri Co.

In 1997, 350 hectares of the then new paddy rice variety "Morinokuma-san" was introduced as a new special cultivation rice in Kumamoto Prefecture within the jurisdiction of Oshima CE and Rokka CE, and new challenges arose.

One reason was that some 40 individual farmers in Kashima had continued to deal with fertilizer suppliers outside of the system for paddy rice fertilizer, which made it difficult to deal with them. We explained to these farmers the purpose of the manual, which states that fertilizers other than those produced by the agricultural cooperatives are not to be discussed in price negotiations, in the course of voluntary price negotiations in accordance with the manual for the introduction of special rice cultivation. In addition, since fertilizers for special cultivation are about 20% more expensive than chemical fertilizers, a competitive bidding system was introduced for five fertilizer manufacturers to reduce costs for farmers, and JCM Agri Co. The JA Kamimashiki Agricultural Cooperative's one-shot fertilizer system for rice and wheat was introduced from 1997 to 2021 as "Morinokuma-san Fertilizer," and with an annual transaction price of 1 million yen with the manufacturer, orders of approximately 2.3 billion yen over 23 years (from 1997 to 2021) have been placed through system utilization, and a movement to utilize all agricultural cooperatives in the Zen-Noh and Keizairen units has been developed. The campaign to utilize all of the agricultural cooperatives in the Zen-Noh and Keizairen units is being developed.

Since 2021, JA Kamimashiki has been contributing to quality improvement and the production of high-quality rice as the first fertilizer for the cultivation of the new paddy rice variety "Kumasan no Shine".

Conclusion

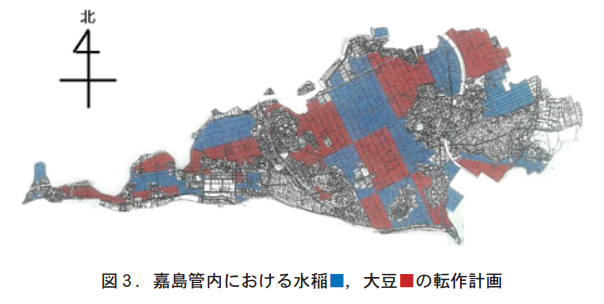

In addition to paddy rice, Kashima Regional Farm is also working on measures to expand production of soybeans and wheat based on future consumer needs. For example, the farm is participating in the government-sponsored Wheat and Soybean Profitability and Productivity Project, and is working on the liquidation and establishment of farmland complexes to strengthen and improve the efficiency of the soybean and wheat production base (Figure 3).

Finally, my motto is "Guidance with passion," and I will continue to lead farming activities with passion to improve farmers' income and establish sustainable paddy field agriculture in the area.

No Soil - No. 14

養分源が堆肥から化学肥料へ変化する時代

−その歴史的経緯−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

The significant effect of compost on crop production can be traced back as far as the time of Aristotle. It was not until the Norfolk farming in the 19th century that compost was actively used to transfer nutrients to farmland and to increase food production (see the May issue of this year's Newsletter). This month's story is about the shift from compost to chemical fertilizers as a source of nutrients. The trigger was the agricultural depression. What was the background?

1. what the Flemish saying teaches

The Norfolk method was a four-year crop rotation (wheat - fodder turnips - barley - red clover) that was derived from the nutrient cycle (Figure 1).

It is a recycling-oriented agriculture in which nutrients in the soil are absorbed by fodder crops (fodder turnips and red clover) that serve as livestock feed, the feed is fed to livestock, the nutrients are collected from the livestock in the form of manure, and finally the manure is transferred to the fields for human food production. This was the very essence of the old adage "No feed, no livestock; no livestock, no manure; no manure, no harvest" passed down from generation to generation in the Flemish region of mainland Europe (present-day southern Netherlands to western Belgium and northern France) across the river from Norfolk, England. This saying eloquently describes the major role of compost as a nutrient transfer material (fertilizer) for maintaining crop production in the European crop rotation.

However, there is another point in this saying that should not be overlooked. The compost is a source of fertilizer, but it is also a source of fodder for livestock. As the Flemish proverb points out, compost cannot be produced as a source of nutrients without producing crops that feed livestock (forage crops) rather than food for people. That is why Norfolk Farming allocates half of the land area on the farm to fodder crop production and adds fodder turnips and red clover to the crop rotation. This has not only increased the number of livestock that can be raised, but also made it possible to keep the livestock in the barns through the winter. As a result, the recovery rate of livestock manure has increased, and the production of manure as a source of nutrients has increased. This has made it possible to increase the amount of manure applied to fields that produce food for people. This has allowed the yield levels of wheat and barley to nearly double at a stroke.

2. alternative sources of compost nutrients needed to escape agricultural depression

Until the use of chemical fertilizers became commonplace, this method of farming became widely popular because of its revolutionary high yields. In the 19th century, British agriculture entered a golden age at the height of Norfolk farming. However, this golden age did not last long. The Cereal Laws, which had previously restricted grain imports, were repealed, and inexpensive wheat was imported in large quantities from the United States and Canada. This caused a major blow to wheat cultivation in the U.K. and led to an agricultural depression. This depression began around 1875 and continued for about 60 years, although it was temporarily interrupted during World War I (McLean, 1991).

The agricultural depression was severe in the Norfolk region as well. In Norfolk farming, fodder turnips and red clover plots, which are grown to feed livestock, generate no direct income. They are grown for manure production as a source of nutrients. In order to get out of the recession, farmers have been tempted to stop the unprofitable forage production and grow cash crops to feed people. This would increase their profits. However, there was a problem. If they stopped producing fodder, they would no longer be able to feed their livestock, which would also mean that they would no longer be able to produce compost, and crop production itself would decline. Therefore, the important thing was to find a source of nutrients that could be substituted for compost. This is where chemical fertilizers, which were beginning to be sold and distributed at the time, came into the spotlight.

3. results of agricultural experiment stations established with farmers' investment

The world's first commercial chemical fertilizer, superphosphate lime, was introduced on July 1, 1843. This was shortly before the onset of the agricultural depression. Of course, chemical fertilizers were not widely used by ordinary farmers. It was still some time before chemical fertilizers became widely available. Everyone was concerned about whether chemical fertilizers, which had never been used before, could really be an alternative source of nutrients to compost. Scientific support was needed to resolve this issue. Therefore, Norfolk farmers funded themselves to establish the Norfolk Agricultural Experiment Station (later succeeded by the Morley Research Center and now The Morley Agricultural Foundation) in 1908 (Figure 2).

Results of a 12-year long-term crop rotation trial at the Norfolk Agricultural Experiment Station showed that when crop residues (e.g., wheat straw and sugar beet tops) are incorporated into the soil with chemical fertilizers, wheat and barley seedling yields can be maintained at the same level as in composted treatments, even without the application of compost ( Raynsand Culpin, 1948). Based on these results, it was recommended that sugar beets be grown instead of turnips for forage and that balayasho be grown instead of red clover (McLean, 1991), provided that chemical fertilizers were used in combination. Thus, concerns about chemical fertilizers were gradually resolved, and the source of nutrients for Norfolk farming gradually shifted from compost to chemical fertilizers, leading to the acceptance of chemical fertilizers in the world.

4. dilemma associated with compost production in recycling-oriented agriculture

The main reason for the introduction of chemical fertilizers into Norfolk farming was the need for land to produce fodder for livestock, which is the key to the nutrient cycle. The agricultural depression made it impossible to allocate that land for feed production. Moreover, as crop yields increase, the amount of nutrients taken out of the field also increases. This requires a large amount of compost as a source of nutrients to replenish the crop. Increased production of manure requires an increase in the number of livestock, as well as more farmland for the production of feed for the increased number of livestock. However, the profitability of that farmland is low. This is the dilemma that arises when trying to rely solely on compost as a source of nutrients in recycling-oriented agriculture.

More importantly, as Liebig, who with Sprengel argued that plant nutrients are inorganic, once criticized, there can be no perfect cycle in any cyclical agriculture. The produce is taken off the farm to be sold. The nutrients absorbed by the farmland are surely taken out of the circulation path. Unless the nutrients are brought in from outside the circulation path, the nutrients contained in the farmland in the circulation path are gradually depleted. Liebig called this plunder agriculture and recommended the use of chemical fertilizers to replenish nutrients.

5. another test to confirm fertilizer efficacy of chemical fertilizers

It was Rose of England who first introduced chemical fertilizers to the world. Rose was also concerned about whether chemical fertilizers were really as effective as compost. He therefore founded the Rothamsted Agricultural Experiment Station on his own to test the efficacy of fertilizers. This was 65 years before the Norfolk Agricultural Experiment Station, the oldest agricultural experiment station in the world. The testing began in 1843, the year chemical fertilizers were first sold. These tests have continued to the present day, some 180 years later. We will discuss the results in next month's issue.